In the world of power tools, choosing between brushed and brushless motors is more than just a technical detail—it directly impacts performance, durability, operating costs, and how well they fit specific jobs. For pros and DIYers alike, understanding the core differences, advantages, and limitations of each technology is key to making smart buying decisions. This guide breaks down the mechanics, pros and cons, and head-to-head comparison of brushed and brushless power tools, backed by real-world data and industry insights.

What Are Brushed Power Tools?

Brushed power tools use a traditional motor design that’s been around for decades, defined by mechanical commutation to turn electrical energy into mechanical motion. At the core of a brushed motor are carbon brushes and a rotating commutator. The carbon brushes (made of graphite or carbon compounds) make physical contact with the commutator—a segmented metal ring attached to the motor’s rotor. When electricity flows through the brushes to the commutator, it creates an electromagnetic field that spins the rotor, powering the tool.

This mechanical contact is what sets brushed motors apart, but it also comes with inherent tradeoffs. The design is simple, time-tested, and widely used in entry-level and budget-friendly power tools—from drills and grinders to impact drivers.

Advantages of Brushed Power Tools

- Lower Upfront Cost: The simple mechanical structure—fewer electronic components and no complex control systems—makes brushed motors cheaper to manufacture. Brushed power tools typically cost 30% to 50% less upfront than their brushless counterparts, making them a great pick for occasional users or those on a tight budget.

- Easy Maintenance & Repairability: Carbon brushes are standardized wear parts that can be replaced quickly and affordably. Many DIYers and small shops can swap out brushes without professional help, extending the tool’s life at a low cost. For example, auto shops often prefer brushed Dewalt DW216 drills because rebuilding them with new brushes is cheaper than replacing the whole tool.

- Proven Reliability for Simple Jobs: For light-duty work (e.g., occasional wood drilling, furniture assembly), brushed tools deliver enough performance. Their straightforward design is less likely to have electronic failures, making them a safe choice for users who value simplicity over advanced features.

Disadvantages of Brushed Power Tools

- Low Energy Efficiency: Mechanical friction between the brushes and commutator wastes 65% to 80% of energy as heat and sparks, resulting in an overall efficiency of just 20% to 35%. That means shorter battery life for cordless models—tests show a brushed drill can bore 276 16mm holes per charge, compared to 397 holes with a brushless tool using the same battery.

- Limited Lifespan & Wear: Carbon brushes wear down over time, usually needing replacement every 500 to 2,000 hours of use. As brushes wear, performance drops (e.g., less torque, more noise) and the motor eventually fails. Under heavy loads, brushed motors can overheat fast—hitting 192°F in 5 minutes of continuous use, which risks melting the motor.

- Poor Torque Consistency: Brushed motors lose a lot of torque under load. For example, the Dewalt DCD771 brushed drill drops from a peak torque of 380 in-lbs to just 120 in-lbs after 30 seconds of driving 3-inch deck screws. This inconsistency makes them ill-suited for heavy-duty jobs like driving ½-inch lag bolts into oak or nonstop industrial use.

- Noise, Sparks & Contamination: Friction between the brushes and commutator creates noise (often over 65dB), vibration, and sparks. Carbon dust from worn brushes can contaminate work areas, making brushed tools a bad fit for cleanrooms, explosion-proof environments, or semiconductor manufacturing facilities.

What Are Brushless Power Tools?

Brushless power tools represent a modern leap in motor technology, doing away with mechanical brushes and commutators entirely. Instead, they use electronic commutation—controlled by a built-in microprocessor (onboard computer) and sensors—to regulate the motor’s operation. The motor design is “flipped” compared to brushed models: permanent neodymium magnets form the rotor, while electromagnetic coils (the stator) surround it. The microprocessor adjusts current flow to the coils in real time, creating a rotating magnetic field that spins the rotor with precision.

This electronic control system is what makes brushless motors outperform brushed ones—it optimizes power delivery based on load, eliminates friction, and enables advanced features like variable speed control and torque regulation. Today, brushless technology holds 63% of the professional-grade power tool market, according to 2023 IBISWorld data.

Advantages of Brushless Power Tools

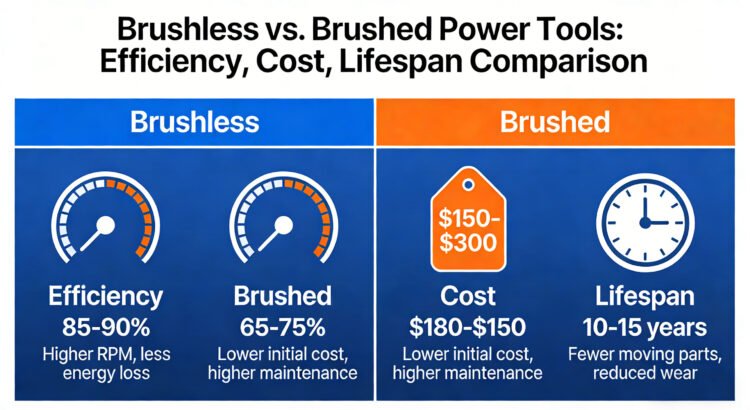

- Exceptional Energy Efficiency: Without frictional losses, brushless motors hit 85% to 90% efficiency (per UL Solutions lab tests). That translates to longer battery life, faster work speeds, and lower energy costs. For example, Houston roofers driving 1,000 screws a day save 2 hours of battery-swapping time with brushless tools.

- Superior Torque & Performance Consistency: Brushless motors deliver higher peak torque and maintain steady power under load. The Milwaukee M18 Fuel 2904 brushless drill, for instance, offers 1,200 in-lbs of peak torque and sustains over 950 in-lbs for 10 straight minutes—unlike the rapid torque drop-off of brushed models. This makes them perfect for heavy-duty jobs like driving ½-inch lag bolts into oak or nonstop industrial use.

- Longer Lifespan & Low Maintenance: No brushes mean no friction-related wear, and improved heat dissipation (frameless construction places copper windings near air vents) keeps motors cooler (topping out at 131°F during extended use). Brushless motors last 2 to 3 times longer than brushed ones, with no regular part replacements needed—cutting long-term costs.

- Quiet, Clean Operation: Without mechanical friction, brushless tools run quieter (40dB to 55dB) and produce no sparks or carbon dust. This makes them suitable for sensitive environments like hospitals, cleanrooms, and explosion-proof workshops, and reduces operator fatigue during long shifts.

- Intelligent Control Features: The onboard computer enables dynamic adjustments—optimizing power for specific tasks (e.g., drilling vs. driving) and preventing overheating or overloading. Some models offer customizable speed and torque settings, ideal for precision work like furniture assembly or electronics repair.

Disadvantages of Brushless Power Tools

- Higher Upfront Cost: Electronic components (microprocessors, sensors, advanced batteries) drive up manufacturing costs. Brushless tools usually cost twice as much as brushed ones—for example, a Milwaukee M18 Fuel brushless drill retails for $199, compared to $99 for the brushed Dewalt DCD771.

- Complex Repairs: Electronic failures require professional service, since DIYers can’t fix microprocessors or sensor systems. This can lead to longer downtime and higher repair costs if the tool breaks down.

- Overkill for Light-Duty Jobs: For occasional DIY projects (e.g., hanging shelves, small home repairs), the advanced features and higher cost of brushless tools offer little real benefit. The performance gap is barely noticeable for light loads.

- Weight Perception: Some users find brushless tools feel lighter (thanks to compact motor design) and less “sturdy” than brushed models, though this is a personal preference rather than a performance issue.

Brushed vs. Brushless Power Tools: Which One Is Better?

There’s no one-size-fits-all “better” option—the choice depends on how often you use the tool, job complexity, budget, and environmental needs. Below is a detailed comparison to help you decide.

| Comparison Factor | Brushed Power Tools | Brushless Power Tools |

|---|---|---|

| Energy Efficiency | 20–35% (high heat/energy loss) | 85–90% (minimal friction loss) |

| Battery Runtime (Same Battery) | 276 16mm holes per charge (example) | 397 16mm holes per charge (example) |

| Torque Consistency | Rapid drop-off (380→120 in-lbs in 30 seconds) | Steady (1,200 in-lbs sustained for 10 minutes) |

| Operating Temperature | Up to 192°F (risk of overheating) | Capped at 131°F (superior heat dissipation) |

| Lifespan | Short (brushes wear every 500–2,000 hrs) | Long (2–3x longer, no brush wear) |

| Maintenance Cost (5-Year Total) | $1,305 (batteries + motor replacements) | $1,075 (fewer batteries, no motor replacements) |

| Initial Cost | Budget-friendly ($50–$150) | Premium ($150–$400+) |

| Noise Level | Loud (65dB+) | Quiet (40–55dB) |

| Suitable Environments | Light-duty, non-sensitive spaces | Heavy-duty, clean/explosion-proof spaces |

When to Choose Brushed Power Tools

Go with brushed tools if you’re an occasional DIYer, prioritize upfront cost over long-term value, or only need tools for light-duty work (e.g., assembling furniture, hanging pictures). They’re also a solid choice for shops on a tight budget that can handle regular brush replacements.

When to Choose Brushless Power Tools

Brushless tools are worth the investment for pros (contractors, roofers, woodworkers) who use tools daily, as well as for jobs that need high torque, precision, or long battery life. They’re also a must for sensitive environments (cleanrooms, hospitals) and heavy-duty work (drilling through concrete, driving lag bolts) where brushed tools can’t perform reliably.

Conclusion

Brushed power tools still have a place for budget-conscious, casual users, but brushless technology is the clear choice for pros and anyone seeking long-term performance and cost savings. While brushless tools cost more upfront, their efficiency, durability, and low maintenance make them more economical over a 5-year period. As silicon carbide (SiC) power devices become more common, brushless tool prices are expected to drop 30% by 2026, making them even more accessible. Ultimately, matching the motor type to how you use the tool and your job needs will ensure you get the most bang for your buck.