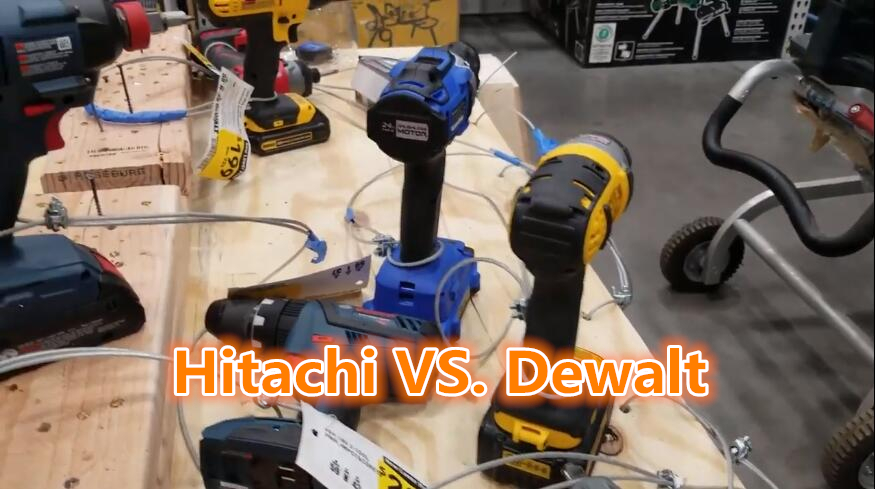

In this article we will compare several products manufactured and sold by Hitachi and DeWalt such as impact drivers, drills, miter saw, table saw, framing saw. The comparison will cover some key criteria like performance, reliability, quality and safety of these devices, due care will be exercise to explain the features and other key factors in an easy and engaging manner to both let you understand the working of these devices and help you decide which product is best suited for your needs.

About Hitachi

Hitachi Ltd was founded by Namihei Odaira in 1910. It is headquartered in Chiyoda, Tokyo Japan. It is a multinational conglomerate which is diversified in to eleven major business segments the conglomerate has business investments in sectors such as Highly Functional materials and components, Telecommunication systems, Electronic Systems and Equipments, Automotive Systems, Construction Machineries, Power Systems, Railway and Urban Systems, Consumer Products and Digital Media, Financial Services.

Hiroaki Nakanishi is the current chairman and Toshiaki Higashihara is the current President and CEO of Hitachi Ltd.

Some of the major electronic equipments produced by Hitachi are LCDs, medical electronic equipment, power tools, semi conductor manufacturing equipments, 2.5 Hard Drives. Test and measurement equipments.

About DeWalt

Raymond.E was the founder of the original DeWalt in 1923. It is popular for its innovation of the radial arm saw. The company was restructured and reincorporated in 1949 as DeWAIt Inc. after purchasing DeWalt Inc, theAmericanmachinefoundry.com sold it off to Black & Decker.

In 1994, DeWalt acquired the German power tool producers ELU. DeWalt significantly improved and increased their line-up of tools using the technology ELU possessed. DeWalt is believed to manufactures and sells over 200 varieties of power tools and 800 varieties of accessories as of a 2001 report. Black & Decker acquired DeWalt’s rival power tool manufacturer Porter Cable and merged it with DeWalt.

DeWalt’s initial line-up included power and hand tools include utility knives, pliers, adjustable wrenches, tape measures, saws, hammers. The line-up was further expanded by introducing machine tools, wrenches, ratchets and sockets in 2013.in September 1, 2016 DeWalt debuted an hybrid voltage battery back which was an Industry first.

Hitachi vs Dewalt Impact Driver

Impact driver is a tool which is used to deliver a quick and impactful rotational force and onward thrust with a strike on the rear with the assistance of an hammer. Impact drivers are generally used to loosen nuts and screws that are frozen due to corrosiveness or over torque by mechanics which are much heavier for other hand tools, impact drivers help mechanics drive screws in to tough materials with less manual power and prevents the drive bits from unnecessarily slipping from screw heads, which would potentially ruin the screw by stripping its head. By reversing the spin direction of impact drivers we can remove stubborn bolts or screws.

Here in this article let’s compare the Hitachi WH18DBDL2 and the DeWalt DCF899P2 20 volt Max XR Brushless High Torque.

The Hitachi WH18DBDL2 consists of a 18 volt Lithium ion brushless triple hammer impact driver, it brings along 2 batteries and a fast charger for uninterrupted productivity, it can deliver 1832 pounds of torque. The impact hammer can run at a top speed of 2900rpm for faster completion of task its 1/4th inch quick change x check allows you to switch bids out for easy trasition between projects, it has a built in LED light to work in dark lit conditions, it is IP56 certified for water and dust resistance.

The DeWalt DCF899P2 20 volt Max XR brushless High torque A” impact driver kit comes with 5.0 Ah dual batter features a brushless motor. It has a maximum torque at 600ft/lbs, with maximum break away torque at 100ft/lbs. this tool has a three speed switch selector, it has a LED light with a 20 second delay to assist in dark lit spaces.

The Hitachi has a 3 hammer impact driver whereas the Dewalt has a 2 hammer impact driver The DeWalt’s feature of pulling the knob to attach the bit seems easier than the Hitachi’s technique of fitting the bit. The triple LED lights in the Dewalt is more handy than the single LED light found in Hitachi. The batteries of the Hitachi seems more compact than the DeWalt batteries.

Hitachi vs Dewalt Drill

The tools commonly used for driving fasteners or making round holes are called drills, either a drill or driver is fitted as a bit, secured by a chunk depending on its use. An hammer function is also Included in some power drills. Characteristically drills are corded electrical driven device with various hand operated types decreasing in popularity with the emergence of cordless battery powered variants gaining increasing adoption among users. The usage of drills can be seen in metal working, wood working, machine tools fabrication works, generally. Exclusively designed versions of drills are used in works relating to space, miniature applications and medicine.

Here we compare the Hitachi DV18DSDL and the DeWalt DCD996P2 20v Max* XR Lithium ion Brushless 3 Speed Hammer Drill Kit. The Hitachi DV18DSDL is an 18 volt hammer drill. Comprising of 1830 BSL. It has 1 LED Light. The DeWalt hammer Drill comes with a heavy duty 1/12th ratcheting nitro carburized metal chunk with carbide inserted for superior bit grip. It comes with 3 LED Lights with 20x brightness. It has a maximum spped of 2000 rpms and maximum speed of 2250 rpm speed during hammer drill mode, it comes with a 2 battery set with 20 volt charger.

Hitachi vs Dewalt Miter Saw

A tool used for making miters and cross cuts accurately in a work piece by pulling amounted circular saw blade or a large back saw blade with a quick motion down on to a board is called a miter saw. A drop saw or power miter saw is a power tools which helps making cross cuts accurately at selected angles in a work piece, these are generally used for trimming, cutting of molding works. Miter saws are usually portable due to their small dimensions with their blade sizes ranging from eight to twelve inches long. Edniehaus invented the power miter saw for Rockwell in 1964. Spring actions, radial arch, blade barking and dust collection are some innovations that are still in implemented during the later innovations of the miter saw.

Here we compare the Hitachi miter saw with the DeWalt miter saw. The Hitachi miter saw is bundled with a single bevel compound miter saw, it comes with a 45 degree bevel and a thumb activate positive meter stopper and dust bags. It is fitted with a elastic hand for better grip. It is fitted with a 15 Amp motor and horizontal angle. It has a 5 year warranty period the DeWalt miter saw comes with double bevel sliding compound miter saw. It has a precise meter system with eleven positive stops and a capacity of 0-50 miter and 45 degree bevel cutter. The compound saw is 10 inches long with machine based fence support.

Hitachi vs Dewalt Table Saw

A wood working tool consisting of a circular saw blade mounted on a arbor is called a table saw, it is driven by a motor. The support for materials such as wood is done by protruding the blade through the surface of a table the saw has versatile uses such as cutting through a variety of materials bearing various thickness levels, these saws can be used for working on wood panels, acrylic, flooring, metals etc.

Here we compare two of the most popular table saw models from Hitachi and Dewalt. the two table saw’s are ergonomic to use with the best features available. These are best suited for use in work sites and work shops.

The Hitachi table saw comes with a 35 inch rip capacity, it is also called job site table saw. It is fitted with a 15 Amp universal direct drive motor that provides high power capacity for caring out a variety of jobs, this saw comes with a telescoping table extension that will provide support for tools as you use it. The DeWalt compact job table saw comes with a maximum rip capacity of 20 inches. It is portable and weighs less and is covered by a steel roll cage to prevent damage caused due to accidental drops .it has a powerful motor which is 1850 watts helps in providing tough power for application.

Hitachi vs Dewalt Framing Nailer

Framing Nailer in order to handle large wood works or projects framing nailers are used, it is used quite commonly for decks, constructing rooms or framing houses. The nailer is used wood siding, wood sheathing, fence building, framing and other major carpentry works. The framing nailers help in driving a number of nails into a framing assembly faster and more efficiently than a skilled carpenter. It should be carefully used as improper use will lead to hazardous consequences. Framing nailers are of two types pneumatic framing nailers and cordless framing nailers. An air compressor is used to deliver air to the tool through the hose to operate the pneumatic framing nailer. The nail is driven in to the wood with the help of a piston which is driven by the compressed air from the hose. The cordless framing nailer has a similar method of working but the pressure to drive the piston typically comes from a disposable compressed air canister that is fitted inside the nailer.

The Hitachi DCN692 consists of a unique air drive system, the nails are fired using compressed air on the basis of increasing power, the power, performance and drive speed is increased with each nail. The run cost is lower due to avoidance of gas cylinders. Reduced service costs as regular cleaning of combustion chamber is not required, maintenance is easy due to fewer components, sequential and contact mode is available with dual trigger option.dry fire lock out mechanism is present to prevent unnecessary activation. Integrated hooks for better convenience. Lithium ion batter with rapid charger and cooling system, it comes with brushless motors.

The DeWAIt DCN692 comes with a dry fire lock out ensuring the tool is protected from accidental firing. Cordless design is a added advantage, contact trigger helps in preventing accidental triggers, two speed levels for optimizing nailer for different purposes. Sequential operating mode helps in precision placement and avoiding bump operating mode. Thumb wheel depth option helps adjust durability and useablility.gas free operation and tool free jam clearance help in reducing maintenance costs.